Haptic Knife Simulator

Introduction:

The process of cutting objects involves many engineering properties that are of interest. These can include several types of nonlinearities, such as large deformations, contact, crack, and propagation. To determine how these nonlinearities transfer to a haptic system, we chose to design a haptic device that simulates a knife cutting through various foods. Since this system has 1-degree of freedom and we already have experience with this from our previous work rendering various forces with position-sensing, we think this idea is a realistic scope for a two-week project. We thought it would be interesting to see how realistic we can make a device that simulates cutting through specific foods.

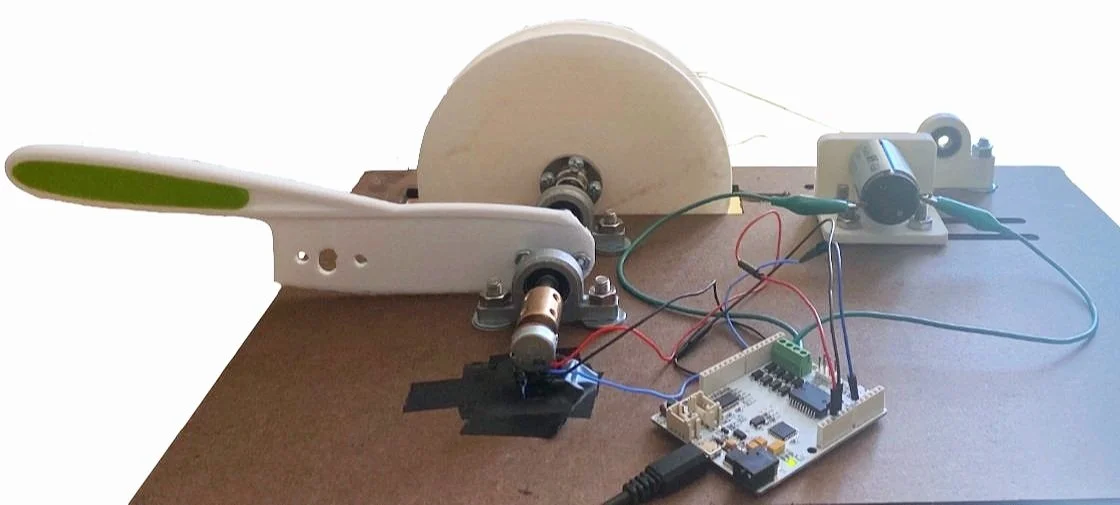

We sought out to develop a haptic knife system that simulates the feeling of cutting through various foods. The potential applications for this concept are vast, from being used for knife-skill practice or being implemented in a VR cooking game. Either way, we thought it would be really interesting to see if we could replicate the force profiles of cutting through different foods. Through the use of a potentiometer, a motor, a capstan drive, additional hardware, and Arduino code, we were able to create a haptic knife that simulates cutting an apple, an avocado, and a marshmallow.

Design

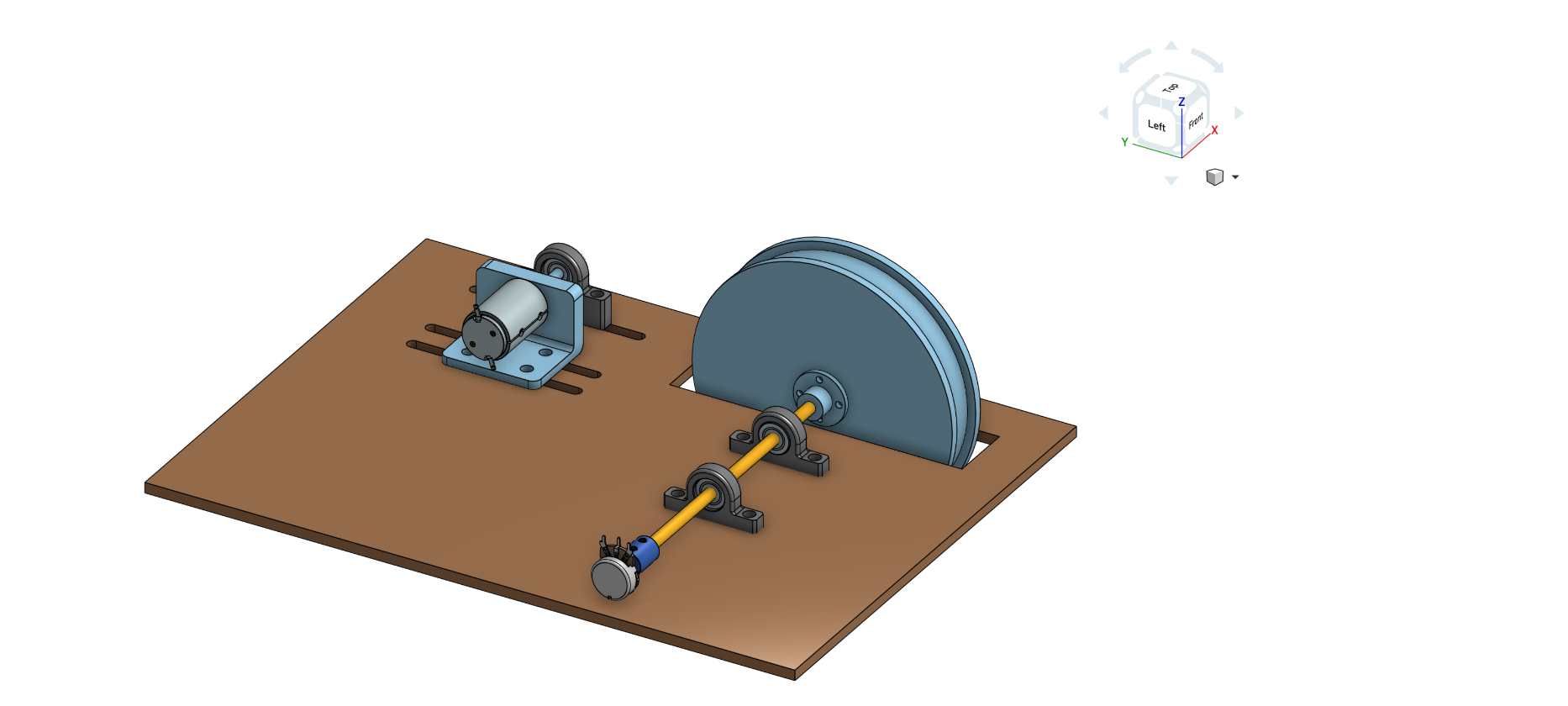

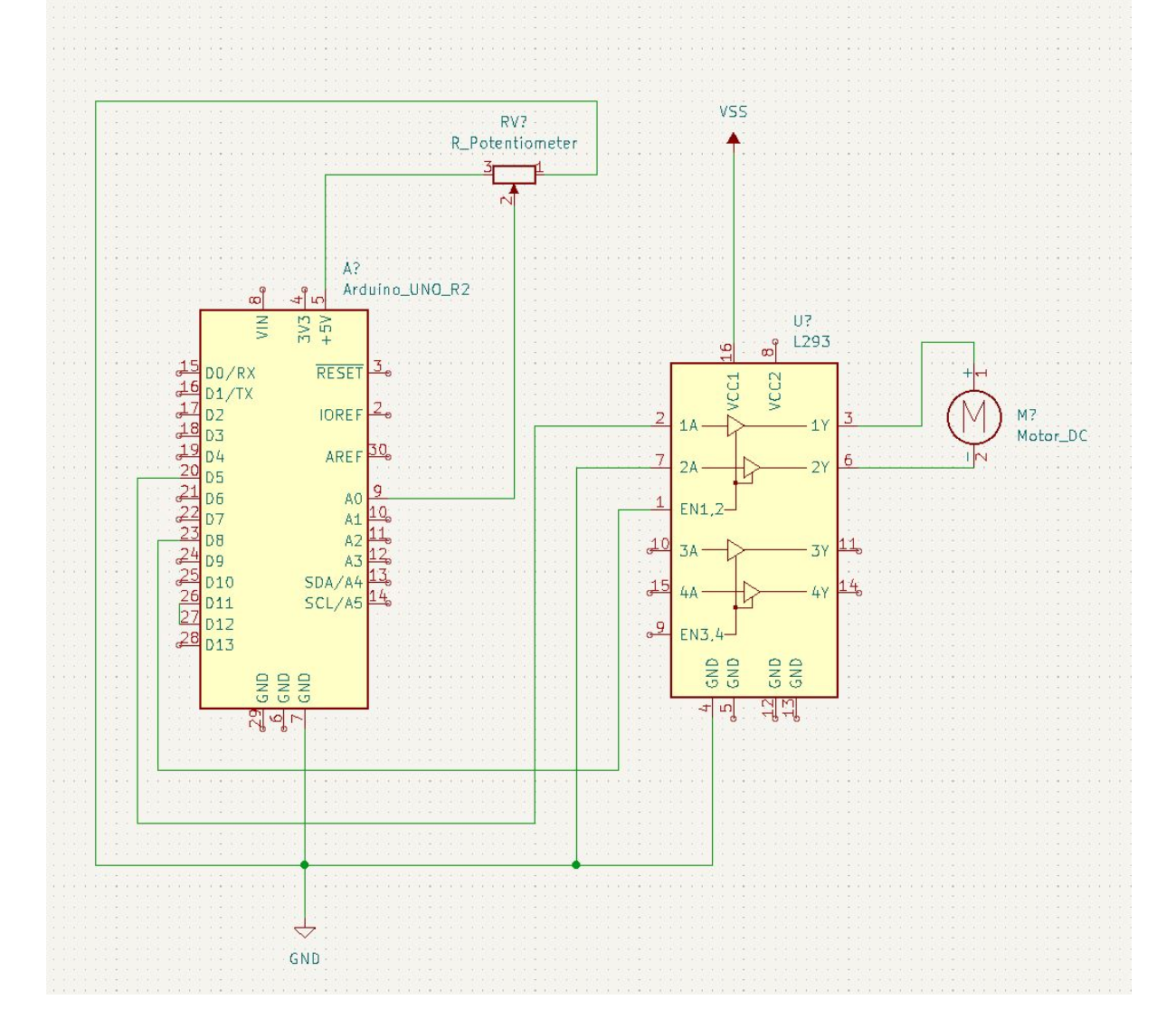

We wanted to create a realistic environment for our user so the device is designed as a table top cutting board. The board was made of 1/4'' duron to mimic a classical wooden cutting board. We drew ideas from the capstan drive and drum system in our hapkit (a haptic device and microcontroller kit) and created a system around these components. However, we wanted to use position sensing as opposed to magnetic so we decided to use a 10KOhm Potentiometer to determine the position of the knife through resistance readings. We use a long steel shaft, which is driven by a capstan and drum system. We used a circular flange that fits onto the steel rod to fasten our nylon knife to the rod. We created two sets of holes in order to have versatility of the knife placement. The drum is connected to the capstan and is driven by an AC electric motor. A potentiometer is attached to the steel rod with a motor coupler and is used for position sensing of the knife. The final CAD of our full system is shown in the image below.

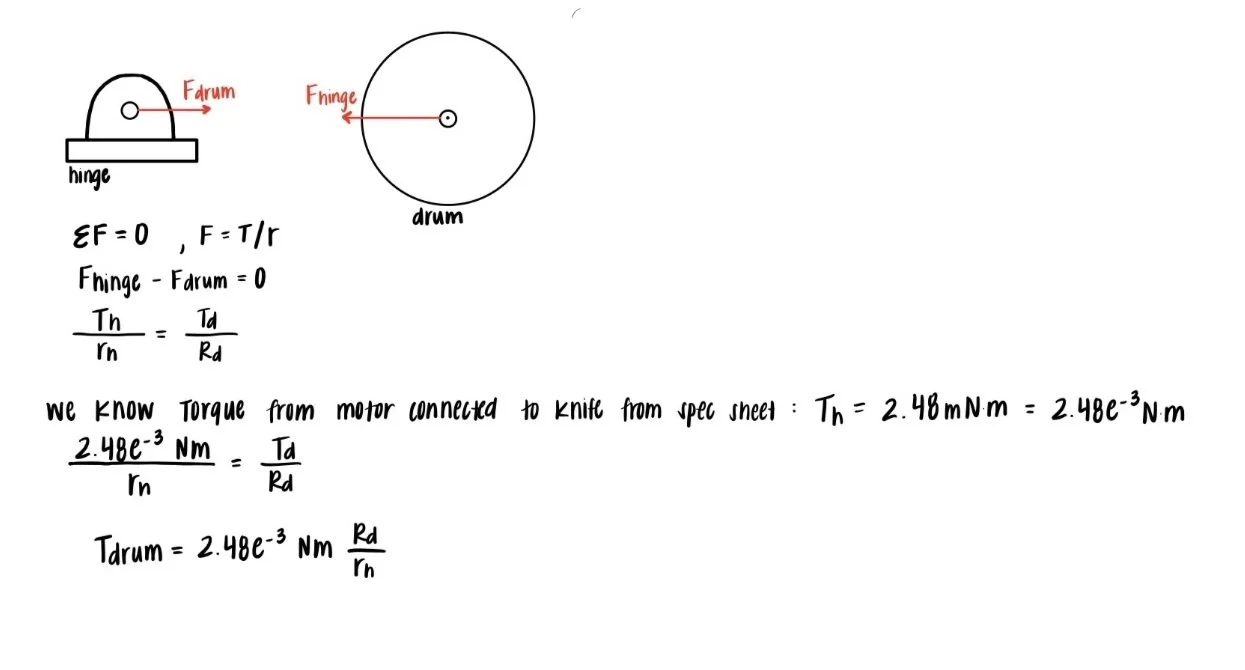

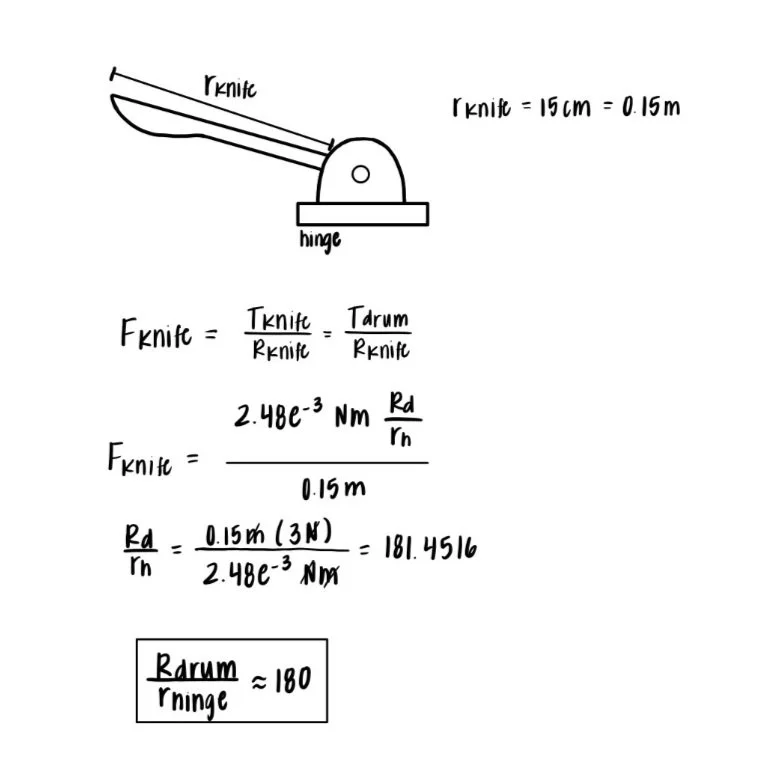

Most of the components were created to be as small as possible in order to make our device relatively portable. However, we did have to calculate the necessary radii ratio of our knife hinge and drum. We performed a static analysis of the forces from the drum and the hinge on the knife. We assumed a maximum force of 3N was needed to create our desired affect on the knife. These calculations drove the dimensions of our drum radius as well our steel rod and flange.

Most of the components for our device were ordered, except for the drum, capstan, duron base, one of the bearing houses, and the cable. All of these components were made in OnShape by ur team and 3D prtined or laser cut. The mechatronics of our system was relatively simple as we only needed connections to our maxon motor, potentiometer and arduino.

Software and Control

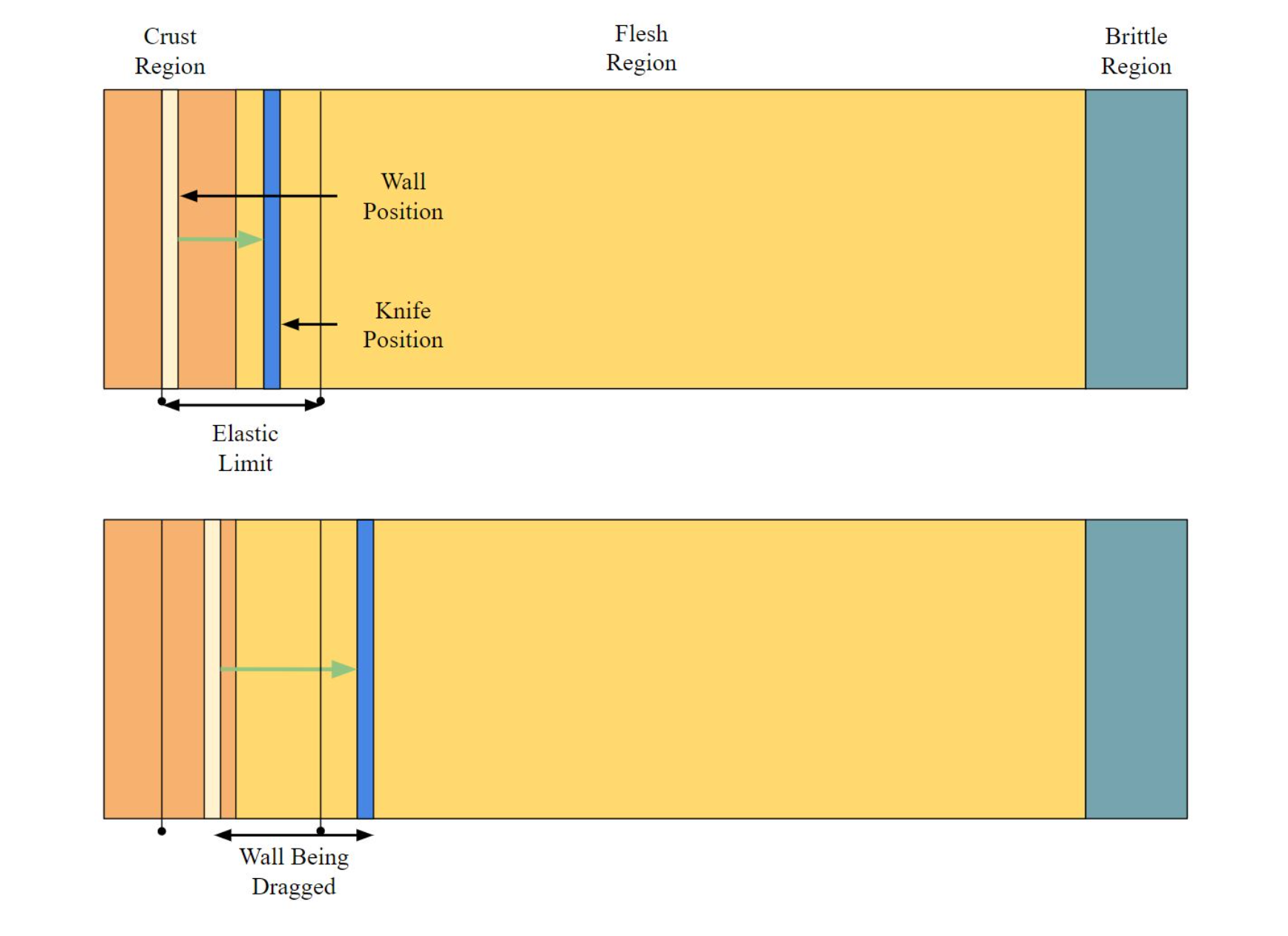

The simulation was implemented by use of a moving haptic wall. This wall can be "dragged" as the knife cuts through the simulated material, and passes through three regions. These regions are the "crust" region, the "flesh" region, and the "brittle" region. When the knife position gets far enough into the haptic wall (called the elastic limit), it then updates the wall's position to the new elastic limit. In the crust region we simulate a harder exterior, and so our force output is maximized. After passing through the crust though, the interior of the item should be softer, so we proportionally reduce the force output by a given factor. And finally once the knife reaches the brittle region, the structure of the item fails, and all resistance ceases.

Now there is some nuance in tuning the above parameters. If we wanted to cut an item that does not have a distinct crust, or at least does not have one that gives significantly different resistance, we could implement this in two ways. We could either drop our crust thickness to zero, or we could set our crust-flesh proportionality constant to 1. In either case there would be no perceivable crust to the user. Likewise we can simulate non brittle items by reducing the brittle region to nearly zero, or can simulate very difficult to cut objects by having a large elastic limit.

Results:

In order to test our device on other users, we clamped our duron cutting board to a table with the drum (which hangs below the board) handing off the edge of the table. In order to increase the perceived realism of the device, we included images of the different foods we were testing. Users were told which food they would be cutting prior to attempting the cut. We created three different food profiles for users test: an avocado, an apple, and a marshmallow. These three food were chosen to their differing mechanical properties. The avocado included a thicker crust that then became smooth as the user broke through the crust wall. The apple had a higher force and a satisfying snap at the end to illustrate the final cut. The marshmallow was much more elastic and sprung as the user attempted to cut through it.

Overall, users felt they could distinguish between the different foods! Most users claimed the marshmallow felt the most realistic due to its significant differing properties and the elasticity that was felt at the end of the cut that pushed the knife back upwards.

Final CAD Assembly

Static Analysis of Drum and Hinge

Circuit Schematic

Diagram of Different Crust Regions